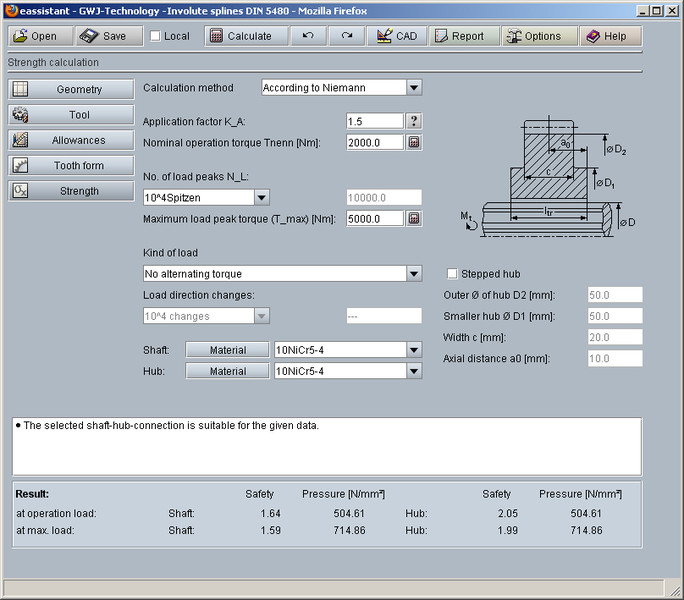

Involute Splines

Buy din 5480-5: 1991 involute spline joints; 30 degree pressure angle; basic dimensions and test dimensions for module 1,5 and 1,75 from sai global. DIN 5480-1 Splined connections with involute splines based DINan N for a hub or W for a shaft, followed by an A for externally-centred connections or an I forinternally-centred connections only in don case of diameter-centred connectionsthen by the module, thenumber of teeth, the tolerance class and the deviation series.

Addendum is the length of the tooth from the pitch diameter to the major diameter.

Addendum Modification is the amount of addendum change of a modified tooth. This value can be positive or negative. If the sum of change to a pair of gears equals zero then there is no change to the center distance.

Addendum Modification Coefficient is the ratio of change of a modified tooth. This value can be positive or negative. If the sum of change to a pair of gears equals zero then there is no change to the center distance.

(DIN 5480) Upper tooth thickness deviation

Chordal Measurement is a straight-line measurement across a specified number of teeth. The range is based on the maximum effective and the maximum actual tooth thickness.

Teeth to Gage Over defines the number of teeth that are used with the chordal measurement. This value is automatically generated but the user may input another value. The value can be reset by clicking on the GearTeq menu item Tools>Reset Chordal Measurement.

Addendum Coefficient is a constant that is divided by the diametral pitch to determine the length of the addendum before any modification. The addendum length of a 10 diametral-pitch gear with an addendum coefficient of 0.8 is 0.080 in.

Dedendum Coefficient is a constant that is divided by the diametral pitch to determine the length of the dedendum before any modification.

Fillet Coefficient is a constant that is divided by the diametral pitch to determine the radius of the hob tip that creates the gear tooth root.

Dedendum is the radial length of the tooth between the pitch diameter and the minor diameter.

(DIN 5480) Designation is a read-only property that displays the parameters of the individual spline.

For example, DIN 5480-W35x2x30x16x8h:

DIN 5480, the standard used

W, W for a shaft, N for a hub

35, reference diameter

2, module

30, pressure angle

16, number of teeth

8h, tolerance grade and deviation

Involute Spline Definition

(DIN 5480) Tolerance Position. Select 'a' through 'v' for the DIN standard. If 'no class' is selected then the individual properties of the gear can be controlled by the user.

Base Diameter is a diameter that is tangent to the pressure angle. The involute curve cannot be within this diameter.

Diameter, Major, Maximum defines the maximum major diameter. This is normally read only unless “No Class” is selected for the Tolerance Class, ANSI and JIS splines only.

Diameter, Major, Minimum defines the minimum major diameter. This is normally read only unless “No Class” is selected for the Tolerance Class, ANSI and JIS splines only.

Diameter, Minor, Maximum defines the maximum minor diameter. This is normally read only unless “No Class” is selected for the Tolerance Class, ANSI and JIS splines only.

Diameter, Minor, Minimum defines the minimum minor diameter. This is normally read only unless “No Class” is selected for the Tolerance Class, ANSI and JIS splines only.

Defines the SAE Nominal Diameter.

Pitch Diameter is the theoretical diameter of the spline.

True Involute Form diameter (TIF) is the diameter of the circle beyond which the tooth profile must conform to the specified involute curve.

Face Width is the length of the tooth parallel to the shaft.

Fillet Radius defines the radius on the tip of the cutter, which forms a trochoidal curve tangent to the tooth root.

Form clearance is the radial depth of the involute profile beyond the depth of engagement with the mating spline component.

Manufacturing Method DIN

Manufacturing Method DIN sets the manufacturing method for the component. The manufacturing method has a direct effect on the dedendum depth. For external splines the options are broaching, hobbing, shaping and cold rolling. For internal the options are broaching, hobbing and shaping.

Measurement Between Pins is the measurement between two pins diametrically opposed in an internal spline and is normally used for inspection. GearTeq will calculate the space width for internal spline if a value is entered for the between pin measurement.

Measurement Between Pins is the measurement between two pins diametrically opposed in an internal spline and is normally used for inspection. GearTeq will calculate the space width for internal spline if a value is entered for the between pin measurement.

Measurement Between Pins is the measurement between two pins diametrically opposed in an internal spline and is normally used for inspection. GearTeq will calculate the space width for internal spline if a value is entered for the between pin measurement.

Measurement Over Pins is the measurement between two pins diametrically opposed in an external spline and is normally used for inspection. GearTeq will calculate the tooth thickness for an external spline entered for the over pin measurement.

Measurement Over Pins is the measurement between two pins diametrically opposed in an external spline and is normally used for inspection. GearTeq will calculate the tooth thickness for an external spline if a value is entered for the over pin measurement.

Measurement Over Pins is the measurement between two pins diametrically opposed in an external spline and is normally used for inspection. GearTeq will calculate the tooth thickness for an external spline if a value is entered for the over pin measurement.

Module (transverse) is used in metric system gears. Module equals the normal module divided by the cosine of the helical angle.

Name defines the name of the part.

Number of Teeth defines the number of teeth for the component.

Part Color sets the color of the component. If the component is the active component then the color used for display is determined by the Color_Active_Component option in the Options menu. To get an active component to be displayed in its specified color, set the Color_Active_Component option to Transparent.

Path defines the name of the folder where the component files are stored.

Circular Pitch is the arc length of a single pitch at the pitch diameter.

Pin Diameter defines the diameter of the pins or wires used with Measurement of Pins. A user defined pin diameter may be entered. To reset the value to the standard value select Tools>Reset Over/Under Pin Measurement in the GearTeq menu.

Diametral Pitch is used in imperial system gears. This defines the diametral pitch in the transverse plane.

Stub Diametral Pitch is used in imperial system gears. This defines the stub diametral pitch in the transverse plane and is normally equal to twice the diameter pitch.

Pressure Angle is the angle of the tooth at the pitch diameter.

Root and Fit defines the type of fit for the component. Select fillet root side fit, flat root side fit or flat root major diameter fit.

The actual space width is the circular width on the pitch circle of any single space. Please consult other gear manuals for a fuller description.

The actual space width is the circular width on the pitch circle of any single space. Please consult other gear manuals for a fuller description.

The basic space width is the basic circular width on the pitch circle of any single space. Please consult other gear manuals for a fuller description.

Space Width Effective Maximum of an internal spline is equal to the circular tooth thickness on the pitch circle of an imaginary perfect external spline, which would fit the internal spline without looseness or interference, considering the engagement of the entire axial length of the spline. Please consult other gear manuals for a fuller description.

Space Width Effective Minimum of the internal spline is always basic.

Spline Fit Class (ANSI) is a user selectable property. For internal splines, the class is always 'H'. For external splines the options are 'H_d', 'H_e', 'H_f' and 'H_h'.

Involute Spline Dimensions

Standard, select between 4 different standards:

ANSI Diametral B92.1 1996

ANSI Module B92.2M 1980 R1989

DIN 5480

JIS B 1603

(DIN 5480) Actual tooth thickness (or space width) tolerance

Teeth to Pattern defines the number of teeth to pattern when creating the model in CAD. The options are All, None, or First 10. If this is set to All, GearTeq will create a pattern that contains all the teeth. This might be very time consuming if there are a large number of teeth and/or the component is a helical gear. If this is set to none, then a pattern will not be created. Set this to ‘First 10’ to create a pattern with 10 teeth that can easily be expanded in the CAD system.

(DIN 5480) Effective tooth thickness (or space width) tolerance

(DIN 5480) Total tooth thickness (or space width) tolerance

(ANSI and JIS) Specifies the tolerance class for ANSI and JIS splines. If “No Class” is selected then the user may enter values for individual parameters of the component

(DIN 5480) Values between 4 and 12 inclusive are valid.

Actual Maximum Tooth Thickness is the maximum circular thickness on the pitch circle of any single tooth.

Actual Minimum Tooth Thickness is the minimum circular thickness on the pitch circle of any single tooth.

Tooth Thickness Basic is the basic circular thickness on the pitch circle of any single tooth.

The effective tooth thickness of an external spline is equal to the circular space width on the pitch circle of an imaginary perfect internal spline, which would fit the external spline without looseness or interference, considering engagement of the entire axial length of the spline. Please consult other gear manuals for a fuller description.

The effective tooth thickness of an external spline is equal to the circular space width on the pitch circle of an imaginary perfect internal spline, which would fit the external spline without looseness or interference, considering engagement of the entire axial length of the spline. Please consult other gear manuals for a fuller description.

Units sets the measurement units for the component; select Inches or Metric. DIN and JIS are always metric units.

Involute Spline Data